Blood in the Water

I was involved in SolidWorks sales from 1997 until 2005. The first three years were definitely the most exciting period of that time. We were the underdog, fighting Pro/E, AutoCAD, Mechanical Desktop, and Solid Edge. In those days we did not know that Pro/E would drift into irrelevance and Solid Edge into obscurity. The fight was challenging, and rewarding when we won, because we were helping people solve technical problems. Over time we won more and more often.

We had a product that we believed in, and its benefits were clear at that time:

- it was Windows based

- it ran on affordable PC hardware

- it was priced so more professional users could access it

During this time we were emerging from an era when engineering applications were expensive in the 5 or 6 digit range, and ran on expensive and hard to use Unix workstations or worse dedicated systems on proprietary OS and hardware. The less expensive Windows-compliant software with the common Windows interface on affordable hardware was a breath of fresh air. After a while, we didn’t have to prove anything to sell SolidWorks, and converting reluctant 2D users became the biggest challenge. The arrogance of PTC killed the Pro/E software, as PTC left CAD behind to focus on Windchill (PLM). Solid Edge lost the battle internally, changing ownership several times, and never landing in a place where it was valued or could get out of the shadow of big brother Unigraphics.

[pullquote]SolidEdge smells blood in the water… Anna Wood[/pullquote]

Fast forward a few years to the present, and the landscape has changed dramatically. Most of the things we found attractive about SolidWorks are no longer relevant. SolidWorks the company is no longer an adorable underdog. Some would even argue they’ve become somewhat out of touch and detached from the needs of real customers. The modern SolidWorks software is no longer focused on mechanical design software built by engineers, but more resembles the sprawling and modularized Pro/E.

We have a different set of values these days:

- consumables (viewers) should be available on mobile formats

- CAD is being treated as a smaller slice of product development technology, making way for “PLM”

- a wider range of users than just CAD specialists need to have access to geometric data as well as product meta-data

Normally mild mannered and conservative, Anna Wood voices a concern on the minds of some SolidWorks customers.

These aren’t necessarily the values of CAD end users, but of the people who view CAD as part of a larger product development technology market. This is the main distinction between what we think of as mid-range CAD and high-end CAD : High end CAD + CAX + PDM + ECO + ERP = PLM. The fact that you can’t buy SolidWorks without getting a pitch for data management, FEA, and CFD is testament to the fact that PLM bundling has been trickling down to the mid-range for some time.

Last year, the CEO of SolidWorks promised to kill off SolidWorks, meaning of course that SolidWorks was going to try to beat the competition to the punch with the next big thing. He made the mistake of saying that “the cloud” is the next big thing in CAD. He was wrong – merging direct edit and history modeling is the next big thing. The SW users reaction to Mr. Ray’s announcement could be called tepid at best. Had he announced that merging direct edit and history modeling would be the centerpiece of the next incarnation of SolidWorks, the immediate user reaction would have been slightly more positive, but the reaction over time would have improved rather than devolving into a lot of user discontent.

It has been my intention for the last several months to avoid opinion-based posts on this blog, trying to focus more on technical issues. But there has been too much chatter recently to ignore, including one twitter exchange I happened to see between several CAD users where there was a lot of doubt expressed in corners from which I’m not accustomed to hear doubt. Anna Wood is a no-nonsense sort, and not generally a “rabble rouser”, but on Twitter this past week, she could be seen expressing doubts about the future of SolidWorks as a tool that she and her company can use for engineering purposes. If someone as level headed as Anna is thinking these things seriously enough to say them out loud and in public, I have to imagine there is a significant number of less connected folks who feel the same trepidation looking into the cloudy future.

If SolidWorks users are apprehensive about the future, who are they looking toward to answer their questions? In the last week we’ve had conferences for PTC and Solid Edge. What PTC has going on with renaming Pro/E to “Creo” is possibly an admirable idea, but has yet to prove itself. I’m of the opinion that PTC hasn’t changed the way they look at the CAD market in 20 years, and Creo is another layer of lipstick on the pig. The purchase of CoCreate was lip service to a trend. Solid Edge on the other hand was done with the hoopla 3 years ago, and is currently delivering ST3 and 4 software that is proving highly usable today, and not just in marketing studies. I think the Solid Edge (and NX) approach to combining direct edit and history modeling is the best in the industry at the current time. It’s an improvement on both current modeling methods.

To me, the resurgence of Solid Edge started with ST3, when they finally signalled that they had a formula that made sense and worked in practice, not just for CAD specialists or for downstream CAD data users, but for everyone. ST1 and ST2 to me were painful shots in the dark. ST3 changed both the direct edit and history modeling games not by one winning over the other, but by combining them. The power of ST3 is that it allows a single model to function in both the direct edit and history schemes at the same time. You can choose one or the other or use both. It uses ordered features (history-based features) on top of a “dumb” model for those functions that you just couldn’t do any other way, like fillets, shell, and others. The “dumb” model is manipulated by direct edit tools.

It’s clear that Solid Edge is gaining a lot of momentum. The growth of sales reported at PLM World was 50% year over year (2009 to 2010). The users are excited because the software is improving and executives are listening. Positive things are happening. This is an extraordinary rebirth of software that has existed 15+ years, and has already seen its ups and downs. Solid Edge executives are saying publicly that they want to own the machine design market. This is a bold statement, and to make it happen, they are going to have to knock SolidWorks from their comfortable perch atop the CAD marketplace, and pass other competitors such as Inventor.

[pullquote]Solid Edge …#1… this is the focus and now is the time Tony Affuso[/pullquote]

And why is now the time? Why does Solid Edge smell blood in the water? SolidWorks prematurely announced huge changes to the SolidWorks software, along with a philosophy shift that brings SolidWorks (the company and the software) closer to Dassault. CAD in the Cloud is an idea you will find little sympathy for in the SolidWorks user base. Making SolidWorks (company or software) more like Dassault or Catia is not something many SolidWorks customers would have asked for, given say 1000 things to ask for. Now is the time, because until SolidWorks releases SolidWorks V6 and it is a total hit with users, a certain portion of the SolidWorks customer base is uncertain and vulnerable. SolidWorks greatest weakness in the last 15 years just happens to be coinciding with the greatest point of strength for the Solid Edge software and company. If Solid Edge misses this opportunity, it will indeed be time to give up in this market space. Early indications – 50% growth from 2009 to 2010 with the same sort of growth showing into 2011 – indicate that they are not missing the opportunity.

Solid Edge is not the only CAD company to see this opportunity, but I do think they are the best positioned to take advantage of it. PTC’s Creo effort is simply not convincing, and whatever Autodesk is doing with Fusion/123D does not appear to be a serious enough effort to compete against anything but Sketchup and Spaceclaim.

Want to read more about what others are saying about Solid Edge ST4?

Roopinder Tara – SE Comes out of the Shadows

SolidMastermind has a web sight with many tutorials on it. Yes you have to pay but $77.00 gets anyone access to the Classic level of SE tutorials for a month. It is a cheap way to see just what can be done and if you should be interested. $57.00 for the basic level. You can get an hour free to see if this is of interest to you.

@Neil

Neil, I am checking to see if the manual in SE is OK to put on the net.

There is a website that has a lots of tutorials, however I think that is for SE subscription users only, but I will look into that.

In SE you have the ability to generate PDFs of the help chapters. I dont want to put something out there if it is copyrighted. I will try to find out if SE has them online somewhere.

@Billy Oliver

Where can I find a manual to look at? pdf preferably

@Rick McWilliams

Rick, if I were you, I would run not walk away from SW right now. We just did. I’m on my 39 day of running a demo version of ST3, while our order is processed.

It’s true SE ST has been the best kept secret in the CAD world for years. Sync Tech is truly amazing. Both for machine parts and sheet metal. People knock SE surfacing, but we all know the Parasolid kernel can do surfacing, look at NX look at what SW has done.

The point is, that anything that SW has done with the kernel, SE will be able to do, any surfacing shortcut, trim, extend or sketching shortcut .

SE in the last 3 to 4 years has been working on technological evolution. While SW has been working on menu bar icons, shading and colors. Every on this blog have been complaining over the last few years about SW development, direction, and why are they not fixing bugs, just interface stuff etc.

Truth is SE has much more capability that SW. I have already seen this in 39 days. And that the neglect and oversight of the market that UG had back in the mid 90’s with SE that allowed SW to blossom now DS has with SW.

The kernel change is going to be long and painful….. What did that CEO say a last year.

SolidWorks CEO Jeff Ray when Ralph Grabowski asked him whether the Cloud version of SolidWorks would be the only version in the future. Jeff replied, “When the pain of the status quo becomes greater than changing, then they will.”

WE have already seen SW stagnate of the last few years. And the Parasolid kernel version will not get any new or revolutionary features ever.

All new development will be in the new kernel, that’s what the SW programmers have been doing the last few years. It is exactly what happened with the UG and SDRC merger or buyout. But UG was honest to their SDRC customer base. And gave them a planned path. But it was not until this year that Siemens has not offered IDEAS-NX as a product for sale. Basically it took them a decade to provide the SDRC users with 100% data conversion. I believe this SW kernel change to Catia kernel will be much the same. Long and slow.

Anyhow you should look very closely at SE, basically it is SW on steroids (the good kind) HA.

People talk about move face in SW, like it is all they need to do direct editing, not even close and SE has move face also.

See attached menus for SE ST3.

[img]http://www.dezignstuff.com/blog/wp-content/uploads/2011/07/All ST3 Main Menus.jpg[/img]

Wow, SolidWorks appears totally awsome clueless. I just love CEO talk.

I am starting a medium sized venture. I do not want to put the project at risk by depending on SolidWorks. Is it possible to buy SW licenses for an old version? Can we run with those for years? I will eat shit for years if I make the wrong decision. The CAD data must be maintainalbe for years.

@matt

Ok I see where you are coming from. There is no doubt that DS are laying the foundations for a level of customer “tie-in” that has not been possible to date. Added to this they also get a bite of the hardware pie that currently goes to Dell/HP etc by hosting data and because this is provided by a third party it is money for old rope. This is the stuff that excites DS shareholders.

As customers the only thing we control is our patronage. Take that away and we are powerless and the dynamics of free market forces change dramatically. It remains to be seen how many companies will put up with this.

@Roger

If it isn’t about CAD, it’s still a vote against the DS way of doing things. The wins I was referring to were accounts that switched from DS to Siemens. The nationalistic stuff has less affect on that, because the account was formerly DS. I think it has most to do with a difference in the direction of development, and that affects CAD and non-CAD PLM components.

Dave

I am no apologist for DS but i reckon Mercedes Commercial moving to NX is more about politics than PLM compatibility (and probably nothing to do with CAD whatsoever). The Germans and French are fiercely loyal to indigenous companies, so for us in Europe it comes as no surprise that a German company will go out of it’s way to buy German.

I know this isn’t the only recent NX win but at that level I doubt the actual CAD system actually plays much of a part in the decision!

Well Lutz let us look at using your same numbers. Does the three percent include lost time from inefficiency of the tool, downtime from the tool, lost intellectual property from the tool, time to convert and rebuild geometery from the tools transition from one kernal to another, lost time as the tool talks poorly like Catia to SW or Catia to Catia does. Does it include time on poor output with bad or unclear drawings and other stuff related to actual production of parts? Your 3% number is based on just what? Obviously some of these questions are based on what I see as near future cloud problems. Some of them are based on todays cad. What was the real cost to Airbus recently for instance? 3% of the engineering department and then add in maybe 15% of the gross of Airbus? I don’t know but it was way more than the 3% tool number and you bet they cared.

Yeah maybe the cost of the software is only three percent of the engineering department but it affects the bottom line of every other department to. Apparently 3% ++++ is enough to get some major companies leaving Dassault this past year and I trust they do have their reasons.

You can see the train coming. What are you gonna do? Read this from the Dassault 3DPerspectives blog: http://perspectives.3ds.com/events/v6-on-the-cloud/

Can the author of the blog really be that out of touch with real customers?

@Lutz Feldmann

I can understand what and why you say this Lutz but many of my customers are self employed contracting design guys and the cost software subscriptions (let alone new licences) for them, in many cases, equals or is greater than 25% of their disposable income. That means four(4) to five(5) weeks of a 48 working year (this assumes they can get 48 weeks work a year) have to be done just to pay for their so called consumer tools.

The view of the value of software is quite different when look at from a corporate and individuals point of view.

Yes CAD is a tool but it is more than a commodity for many.

It is the “customer driven company” attitude that concerns me. (sarcasm alert)

Solidworks either does not care about serious geometry bugs, or is unable to solve the problem. Users are stuck unstable models that may rebuild today but not tomorrow. I believed the solidworks hype for a while and then it became too obvious.

I use complex surfacing driven by relational geometry. I will consider SE as soon as they get some nice surfacing. Maybe TSplines will migrate in that direction. I really am rooting for Solidworks to fix the bugs and polish the tool.

And that is exactly what it is – just a tool. A tool where engineering companies are spending less than 3% of their overall budgets. To some extend this CAD discussion is really boring. Maybe those CAD related sales and marketing folks should consider thinking more about the customers business issues and should realize that CAD is commodity software!

Kevin,

Agree… it’s what I believe Dave and I have been saying all along. But the real reason why so many Solid Edge users are very excited, is because Siemens/Solid Edge Development and Marketing have embraced that same philosophy and are pouring tons on resources into making SE the “best in class” MCAD product. But hey if you don’t see the similarities of an arrogant PTC sitting back on its laurels while SW was nipping at its heels, then good for you. As you stated, “at the end of the day, it’s just a tool”

Ciao!

Bob and Dave, clearly you sit on one side of the fence and I sit on the other. I respect that and it is no problem to me at all. As I said (and as that Boeing story states) it is the human factor that always screws things up – rely on technology too much and you end up getting burned.

When all is said and done, I’m generally happy with the technology decisions I have made and I think that for what I do and the funds I have available, I have the best tools for the job. But at the end of the day it is just a tool, the most important user enhancement is me and my staff.

I think we’ve said all that needs to be said.

Sorry but that was opinion by some and not the true story. It had nothing to do with metrics versus Imperial units… it was due to the complicated specification of using Titanium Fasteners with carbon Fiber. Boeing has been using CF construction for over 30 years and it was mostly due to inexperienced European Suppliers not being familiar with Carbon Fiber construction as well as I’m sure language barriers.

The fastener in question won’t sit properly in the hole unless the top of the hole is widened to accommodate a bevel, a curved join between the head and the shank of the fastener. The mechanic has to prepare the hole by cutting it wider at the top, first consulting a specification to find out exactly how much to cut.

But the documents were confusing. The regular spec document for installing fasteners sent the mechanic to another spec if composite plastic was being drilled. This spec then correctly sent the mechanic back to the first if the fastener head was on the titanium side, as in this case.

http://seattletimes.nwsource.com/html/businesstechnology/2008413389_dreamliner20.html

But the A380 was truly a conversion problem and Dassault can take 100% of the blame for that.

Now that I can have a real “Chuckle” about!

“Is CAD data any more at risk than financial data?”

Online banking security is another one of your canards. If I loose $1,000 due to bank fraud, my Bank will refund me $1,000.. it’s pretty straight forward. However if I loose a drawing representing IP, just how much is it worth? And good luck collecting on it when your ripped off by unknown people in foreign lands. Point is this, it is very difficult to place a true value on IP let alone what a drawing represents. If SW goes to the clouds make sure you read the fine print on this. That will tell you everything you need to know.

Everything else on the web is traceable to some extent… even Congressman Weiner’s Wiener! IP on the other hand is a very different kettle of fish.

Ah yes the cloud.

http://www.zdnet.com/blog/igeneration/microsoft-admits-patriot-act-can-access-eu-based-cloud-data/11225

I think this article sums it up rather well. Let us look at the progression of government of the czars by the czars and for the czars. I have my original SS card. On it it says for tax purposes only and not to be used for identification. I get married in 1986 and my wifes new SS card says “property of the federal governmant to be surrendered on demand”

I see the penchant for intrusive power crazy government around me every day and it is getting worse quickly. Just for this reason alone I would never break my customers confidentiality by going to the cloud. This does not even get into the 40 questions I have asked about the cloud that no cloud proposing cad company has definitively answered yet.

Homeland Security is going to be what they want it to be on any given day and you all in England with your proprietary data are just as vulnerable as us to government hack jobs. I can see it now. You sell parts to a company that sells parts to some arab bunch and now you are in the middle of it because you have your stuff on the cloud. Mine will be on my own server and at least they have to have a subpeona to get it.

Every day I see more and more the wisdom of never going to the cloud. Bob has this one right. I am not going to sit still and let a company shove their piracy problem off on me as their quick and dirty fix. Any program I use that intends to force me there will see their last dollar from me that day they announce it.

CAD data on the cloud is a bad dream. This is a large amount of data that represents a lot of work. If this data becomes corrupted, partly corrupted, unreliable, inaccessible, or has limited access there is a lot at risk. An encrypted database is ideal for a catastrophic loss of data. Solidworks CAD data is a terrible inefficient mess that is 1200 times larger than necessary. I have no confidence that Solidworks understands CAD data. Solidworks will have to guarantee cloud data integrity. No insurance company will underwrite that kind of risk.

CAD software on the colud really sucks. Internet bandwidth is just not good enough everywhere that I work. They just want to stick users with an ever increasing monthly bill holding their data hostage. The processing power of engineering workstations is considerable. That will not be cheaper at a server farm.

Bugs, bugs, bugs. Solidworks cannot see them. They do not fix geometry bugs or relational bugs. They do not use the software and think that we will not notice bugs. We have lots of trouble with every new release, many users stay with the old version to avoid the new bugs. When this is not an option we will suddenly find models failing or corrupting the database. Maybe next patch will be better, until then it is ok to lay off those engineers.

Kevin,

I find your enlightened view of the CAD world very refreshing. Well done!!

The Airbus CATIA v4/v5 story if anything details why it is important to upgrade. V5 had more functionality in harness design than v4, but the main issue was one of management of the processes and too much reliance on virtual mockups. Having said that 20/20 hindsight is a great thing is it not. It amuses me greatly that when things like this happen all the competitors rub their hands with glee and the so called industry pundits come out and spout yet more rubbish about things they have zero experience in.

Personally I wouldn’t even know where to begin trying to design and integrate cable harnesses into a beast that size – and remember at that point in time it was the biggest most complex virtual mock up ever done – true state of the art.

Besides, as I said the human factor is always more dominant. Do you not recall the delays on the Dreamliner due to fasteners being specified in USA imperial units rather than metric? I bet Airbus had a chuckle at that one…

http://metricviews.org.uk/2007/11/boeing787-grounded/

The point is, CAD is just a tool, no matter if it is cloud or desktop, NX or CATIA, SolidWorks or SolidEdge. All these great knowledge based systems are all well and good but when the end user starts to rely on it too much that is when trouble starts. It is nice to know that even the biggest companies balls things up….

Indeed lots to think about Bob. When it comes to placing confidential data on an encrypted secure server, with data retained in a database format that (presumably) only the CAD application designed for it can understand, do you really think that is less secure than emailing drawings or data to customers who will pick up emails on their smart phones, then forward to their suppliers in China? Like I said, there is a lot of nonsense talked about data security. The reality is that the least secure system is flesh and bone.

But the real issue here is that I will be paying SolidWorks to host my data, and part of that service agreement will include terms on data access and maintenance of the data – in other words I am paying them to watch over it. If (when this is finally released) those contracts do not include this then nobody will go cloud. It comes down to this. I use online banking. My customers all use online banking. My customers all use online services to support their business in terms of placing orders with suppliers, and working with management accounts. What is so different here? Is CAD data any more at risk than financial data?

One issue I have with cloud based services is this. What happens to the data if I choose not to keep on using the system? Unlike many here I actually have direct experience of this through being an ex customer of Think3. When that contract ended (because they wanted more money) I was cut off. I could view my data, but could do nothing with it. This is the one obstacle I have for implementing a full on subscription/rental system.

Let’s wait and see what the offer is. But I’ll tell you this. Every CAD vendor is watching this very closely. They all want SolidWorks to succeed as they know damn well that in the long term this is the way things will go. In truth, I think in future if we want to play we need to pay. It will become like your utilities bills (as many have said). For us CAD pioneers this will be a total change to the way we know and understand the market. Times change.

Kevin,

Thanks for your response. But as Matt points out it seems to be a “classic” list compiled from those pushing cloud computing. And I don’t doubt SW’s as well as many Software vendors interest in the cloud is to clamp down on pirated software. As far as the rest of your list, every so called benefit for the User is dependent on mostly promises that the Software industry can’t even deal with effectively today… how is it that with CC these security issues will just magically disappear? I don’t expect you to answer that, since you’ve already admitted, that these unknowns need to be addressed. And non of us will sort it out here…. we can only wait to see what unfolds.

But here’s one area you need to consider, and I sincerely doubt will ever be addressed in a manner satisfactory to the “owners of the data”. It sounds like from your posts that you are a consultant or service provider to other companies. But either way there is a huge IP issue with regards to NDA’s and other Confidential Data being placed on someone unknown server on the cloud. I doubt you will be able to get your customers permission to allow and data you to develop for their products without breaching your confidentiality agreements. Maybe the UK is more lax, but here in the USA, I wouldn’t even try to convince my customers that “their” data is out in the wild somewhere. Once the hackers know that there’s IP sitting out there for the taking, they’ll go after it “Like White on Rice”…. and that’s Chinese Rice we’re talking about!

So in my opinion you’ll be giving up your security for your CAD vendors bottom line. Piracy is Piracy… and the people who are pushing the cloud are simply trading in their problem for you to deal with. My take on this is that maybe, and I mean real maybe, we’re looking at 5 to 10 years before the Internet proves itself reliable and secure enough to support Cloud Computing.

Oh and your point #9 up there… Legacy Data is not an issue with Solid Edge/Sync. But if SW abandons Parasolid and moves to the Dassault Kernel, then I think you have to concern yourself about what you’re going to do with all that “legacy” data of yours. From what we’ve seen, Dassault’s record on this is less then stellar. Just ask Airbus: http://www.cadalyst.com/management/what-grounded-airbus-a380-5955 And to further this point, as Matt points out above:

“5> Potentially. Again, speculation. Plus, would you say that Catia is more powerful than NX, given the recent raft of automotive accounts switching from Catia to NX?

There seems to be a lot of companies rethinking their investment in CAD Software and so I doubt these same companies have the stomach to have their data in a clouds too..

Lots to think about…

No worries Matt, couldn’t figure out the purple bit myself (I’m sure there is a tag you can add but that is way beyond me!) discussion is what keeps us sane 🙂

Like the quote as well…..reminds me of that other one I heard – “if you don’t want your sex tapes to go on the internet, don’t video yourself having sex!” 😉

@Kevin Quigley

Kevin,

My response should have been mostly in purple, and read with a circus announcer voice. I welcome other points of view. Still, we don’t have to agree.

“… you should put on the cloud only what you would be willing to give away.”

http://money.cnn.com/2011/06/22/technology/dropbox_passwords/index.htm

Matt I’m not going to get into a mud slinging match here, life is too short. My comments were in response to a request made by Bob who asked what I thought could be benefits. Unless I am mistaken few people actually know exactly what SolidWorks is planning, so everything we discuss here is pure speculation is it not? Or do you know differently?

Maybe I prefer a more balanced discussion. Of course there are unknowns with the cloud delivery, but the simple fact is that most of us here have no idea what is coming.

My outlook on these things has changed in the last 18 months simply because I have been fortunate enough to be exceptionally busy and have had to take on staff. So I have gone from a one man band to a 2.5 man band. For my size of business – where all we do is sell out time and knowledge – software is the biggest overhead aside from salaries. Software and the management of the data is what takes up the time and cost.

So yes I do “whine” about cost and I will continue to “whine” about cost. Truth is Matt, I would have bought one, possibly two more licenses of SolidWorks in the last year, had I been able to buy at USA prices. I would have upgraded to Premium years ago, had it been at USA pricing. So if going cloud even makes the software pricing more level that alone is reason enough to switch. But better, is the opportunity to license modules or extra seats for a short time frame to cover projects.

Amazingly enough I do read the news. I also take a balanced point of view. Do you really consider a thumbdrive with gigs and gigs of data more secure than an online encrypted data format? Of course you need hardware of some kind (I mean really – unless you different I don’t think neural CAD is out there yet is it?), but until we see the format of the cloud delivery we will not know the connection requirements to access the data. The benefit of this – as I think I pointed out – is that all my files are held online so I never forget anything, I don’t have to worry about backups, I don’t have to worry about my 1TB harddrive frying and losing data locally – all that is off loaded and for me at least that has value. So in my eyes from my business needs it is a benefit.

You seem to be shooting back with “speculation” a lot Matt but quite frankly most of what I’ve read on this blog in recent months is just that – speculation. All of which is good fun, and I for one appreciate and enjoy reading it for what it is.

So here goes for some speculation in answer to your points:

1. Read above

2. Speculation! Personally I don’t really care what platform it runs on – all I know is I won’t be running it on an iPad ‘cos I don’t have one (or want one – and I am an Apple guy).

3. Speculation, perhaps. But if it is to run on generic platforms then than implies that the delivery of the data to the system must be streamed in some way, so maybe the grunt work is being done at source. Who knows….

4. Not speculation – I am quoting several SolidWorks and Dassault employees from the CEO down who stated “the cost of ownership will be less”. Of course I prefer to believe that to be true, but others may not. Their choice. What I suspect may happen is that in some markets the costs will be standardised due to the common delivery stream, so the purchase costs may well be less but I suspect they will hope that by opening the modular nature to all we will buy into the system more and end up making more money that way. That is what I speculate at least.

5. Potentially yes. Do I think CATIA is more powerful than NX? I think it has more all round capability. CATIA is the workhorse for most major aviation businesses across the globe – Boeing, Airbus etc. BMW, the world’s most profitable auto manufacturer has committed to CATIA v6. Renault Group, is CATIA, VAG is CATIA, LandRover Jaguar are CATIA – some pretty major names there – I don’t think Dassault are losing that much sleep yet. A lot of the recent successes for NX have nothing to do with “power”, but more to do with politics and standardisation of data formats or company mergers. Mercedes switched to NX, so what – how much of that was pressurised by Siemens? Chrysler etc did too simply because they are owned by FIAT who use NX. I don’t pretend to know much about enterprise systems, but I know that all my customer who use CATIA have grown in the last few years, all swear by it (as opposed to AT it) and have no intension of moving to NX or any other system. So if it means that me as a lowly SolidWorks user can access that club then great. Even better if it means I can buy into CATIA functionality or even offer an upgrade path.

6. See 4 above – same argument. Of course it will cost money – but that may be more cost effective than me setting up my own server farm, running my £2000 workstations flat out for days and seeing my electricity bills rocket. Once we see the offer, we can work out the figures, but let me tell you right now Matt that I use render farms today because it is more cost effective than tying up a machine for days, or when I need the visuals back pronto. The bottom line is – if the project returns can sustain it then we use it.

7. All true of course, but frankly you run more risk of having your card cloned when you pay for fuel than you have of any of your details getting harvested when using a secure – legitimate – site. So what do we do? Sit in out bunkers with the lights out watching our backs or do we push the boundaries and try to make things better for all? I know what I prefer. To be truthful Matt, online security is like security threats of all kinds. Should we stop doing things just because it might happen? Or do we get on with it but just remain vigilant? But the thing is, it it does eliminate piracy this will give me a competitive advantage.

8. True, but I am not talking about incremental saving that cuts into your process every few mins. I am talking about that demo Mark B. did where he crashed it and then restarted at exactly the same point with no loss of data at all.

9. Speculation! In order for people to move to another system they have to be able to afford to implement it and they have to be able to utilise their legacy data. I have discussed this at length with several SolidWorks customer here – some have a few seats, some have 20. When they introduced SW to their companies it was the first 3D CAD system they used. Their usage has generated so much legacy data and so much dependence on that data that they are unlikely to switch simply because the costs and interruption to business would be too much of a hit. 9 times out of 10 when a company opts out of maintenance it is because they cannot afford it – so ask yourself if they could afford to buy multiple seats of a more expensive system to replace SolidWorks (and every major system is more expensive than SolidWorks – like for like – over here). There would have to be some serious discounting going on to force a switch.

I think the culture here is different to the USA. Most SolidWorks users here don’t actually care too much about the software – they just want to keep their job, do it, go home to their families and friends – I honestly have not heard anybody I deal with raise any concerns about SolidWorks future – it is very much a case of we’ll wait and see. For most users the system works well as it is. Most people don’t think SolidWorks is going to throw everything away and force users to a new platform without offering some escape routes or options.

10. No more insecure than logging onto your email from an airport lounge – you pays your money you takes your choice (of risk). Of course I will continue to cart the laptop around – if only to pretend to be cool with my 17″ MacBook Pro 🙂 Besides what else am I going to watch all those YouTube software demos on?

So….as Max says….let the wild rumpus begin!

@Kevin Quigley

Kevin,

You sound like you have drunk the koolaid.

1> Thumbdrive with gigs and gigs of data fits in your pocket. Plus, your statement isn’t true at all. It is only available where you have hardware and a sufficient net connection. And are you everywhere all the time? Is it really a benefit to have your data exposed in places where you don’t need it?

2> Ok, you’ve got a point.

3> Complete speculation. Plus, you know it’s going to be dependent on a pretty substantial net connection.

4> Speculation. You don’t know how SW is going to implement this. Plus, you’re the guy whining about cost. Do you really think the cloud will be cheaper than local install??

5> Potentially. Again, speculation. Plus, would you say that Catia is more powerful than NX, given the recent raft of automotive accounts switching from Catia to NX?

6> Potentially. And you can bet, Mr Cost Conscious, that distributed computing server software is going to cost more, even when you supply your own hardware. This stuff is licensed per core.

7> HA! Do you read the news at all? Hacking and identity theft are right there to take the place of piracy.

8> Existing SolidWorks has all of the capability to save incrementally that was demoed on-stage at SWW2010. People just don’t use it. It has been there for years, and people don’t use it.

9> And the people who would have been on older versions will now be on other software altogether.

10> Again data security.

So you’ve got 1 real benefit.

OK Bob I’ll bite 🙂

Benefits of cloud delivered database CAD:

1. All your files are available all the time, anywhere.

2. Hardware independent – can run on Macs, Windows, Linux….

3. Likely to be less dependent on higher end workstation specific (and costly) hardware such as graphics cards, RAM etc.

4. Easier to add functionality/users to existing contracts for short or long term (so when I employ a freelancer for a few months I don’t have to buy another license, I can just add them to my existing ones for a specific time period).

5. Potentially opens up more functionality for modelling and collaboration if it taps into the CATIA structure.

6. Potentially offers extra solutions for distributed rendering and analysis – for example running a SolidWorks animation via the cloud could deliver results in minutes as opposed to hours.

7. Eliminates piracy – so all those buggers who run pirated versions are screwed, and means the software vendors can reduce prices (believe that when I see it!!).

8. Crash proof – if the final result is like the original demo at SolidWorks World, we lose no more work.

9. Everybody on the same version – so no issues with backwards compatibility (yes I know this is a controversial “benefit” but I see it that way for my business).

10. Potentially feasible to log into your CAD space from anywhere – so no need to cart around a laptop with all your files (and the security implications of that) as you can log on from the customer site and show a model.

There are many more benefits but that will do for now.

As for the add ons, I have no idea what will happen to them. My point was that those add ons are here and now and making money for my business right now. I am quite sure SolidWorks will have a migration path for the add ons in some form or another.

The reality of course Bob is that I don’t know if all this will pan out. All I can comment on is what I see before me. if it all works and delivers what it promises I will shift to it as the benefits outweigh the drawbacks – especially for a smaller business (if only through the removal of so much IT related issues such as backups, hardware compatibility etc). For larger enterprises I’m sure SolidWorks will have some kind of localised network based solution, who knows (and to be frank I don’t really care what a multinational does as it has zero impact on my workflow).

I’m not going to go into the drawbacks as there are many – but most of these relate to unanswered questions that may or may not have a simple answer. My biggest concern is the online access issue – but that has been discussed at length here and other places so I’ll not add any more to Matt’s storage space by rehashing it all again.

Kevin,

Curious as to what your thinking when you claim to “see a lot of benefits” with the “cloud” Also what happens with your add-on programs such as Tsplines Zygote Driveworks if SW is cloud driven.

@Dave Ault

Lots of hypotheticals there Dave 🙂

As you probably know I have changed CAD system many times in the past. As a VX user like yourself I have persevered with other systems without any long term success. The reason I moved away from those systems was either one of increasing costs of operation (Think3) or the software not offering enough return on investment (VX). I have no problem paying for software IF it makes my job easier and if I can get ROI within 12 months. I can do that easily with Solidworks (even at UK pricing), but I simply would not see that ROI with NX or CATIA at UK pricing.

I would only consider changing if I felt the ROI was starting to swing in the wrong direction, or if the functionality differed from the needs of my business in the future.

Nobody really knows what is going on with all the cloud stuff. I have, like many others, concerns about going this route, but I can also see a lot of benefits. All I can say is that for now and the immediate future I am happy with Solidworks. it does everything I need it to do and more. Another factor in the equation is that a lot of ground breaking add ons aimed at MCAD come to the SolidWorks platform first – because that is the market leader. Take TSplines and Zygote Human Factors, and Driveworks. 3 fantastic products, all developed for SolidWorks.

The more you invest in add ons the less likely you are to switch products. The more you invest in a platform the less likely you are to switch. When I started my business in 1990 I bought Apple hardware because at the time it was the fastest and the best. Because of that investment I continue to use Apple macs to this day – they still offer me ROI and unique features that make my job easier (and I also have Windows 7 workstations as well – and they are pretty good too).

The bottom line Dave, is I will change tomorrow if I see a product that will earn me more money and get me home to my family earlier each day. If cloud SolidWorks does this I see no reason to move away. if something else offers it I will switch.

Just a hypothetical here Kevin since Dassault is holding it’s future for SW cards close to it’s vest. What if they do change the kernal for real and that does not work out? What if they do go to the cloud and it turns out that due to infrastructure problems beyond their control it proves unuseable for any but the smallest of files. You have mentioned for a while now a lot of reasons for staying from costs to capabilities but things are changing in a big way. So what if any event would cause you to consider changing? I think you are pretty well up to speed on a variety of cad programs so I am interested in your thoughts here.

I don’t understand the double standards on CAD costs either and bring it up when I can. It is not justifiable in any way except to the bottom line of unethical MBA CPA types who don’t want to do more to earn more.

@Bob Mileti

Bitter reaction? Come on Bob, that’s a bit strong 🙂

The only bitter reaction I have is when I look at how much it costs to buy software here in the UK :).

Let’s just agree to differ in our outlook. Surfacing is critical to me – and no, you do not need Alias or any other “proper” ID package to do that – trust me, I’ve done enough benchmarks over the years to know the most critical factor in creating surface models is the person creating them not the software. Alias is nice but is possibly one of the buggiest application I have ever used (and yes we did look at it again last year).

You might gather that I do regularly assess other systems – I am constantly on the lookout for something that will make a real difference to our workflow. In this last 6 months we have invested in Modo and TSplines. We are considering Rhino and TSplines for Rhino as well. We also invest heavily in rendering systems and associated hardware.

There is – unfortunately – no magic app that does everything for everybody, and is sold at a price that is a “no brainer” purchase. As I said earlier, I am sure NX would meet most of our needs in terms of surfacing power, but with great power comes great cost (both in capital outlay and retraining).

As an industry customer and watcher I actually don’t see Siemens as the new driving force (getting back to topic). In this market, there are two dominant forces -Autodesk and SolidWorks. The only company – and I mean the only company – that has a true joined up product strategy across every major industry is Autodesk. They have been quietly buying and adding functionality to their products and whilst Inventor doesn’t really compare to SolidWorks (or SolidEdge), it is improving rapidly. Autodesk have their own direct modelling system, they have all the Alias technology, they are integrating with visualisation and animation in new an interesting ways, they have a good portfolio of simulation tools now, and are starting to offer suites at prices that do come into the “no brainer” category.

Most importantly they offer solutions across all industries and are the dominant force in AEC.

I am fairly sure in the next few years Autodesk will start to capitalise on all those buyouts and you will start to see Inventor become the dominant force it has always threatened to be. It is just a question of joining up the dots…..and those dots are getting joined more and more with each release, and often in ways we would not consider that really do offer something unique (consider the integration of Moldflow with Showcase – realtime feedback on moulded part defects showing the visual effect of mould layout decisions – seriously impressive for those that need it).

In the meantime I’ll keep watching, learning and considering options. As soon as my choice of CAD system impacts on my ability to do the job effectively, it is time to look at others. Until then I’m happy to plod on with SolidWorks.

Of course of Siemens PLM wants to lend me a copy of NX for a while I’ll be more than happy to do a long term assessment 🙂

…it’s already installed…

The message is: Write more controversial posts 😉

Seriously, I could care less about SolidWorks technical posts, but put up something that pits SE against SW and I’m there. I think you need to rake Inventor and Inventor Fusion over the coals next since Carl White felt the need to try and promote it here 😛

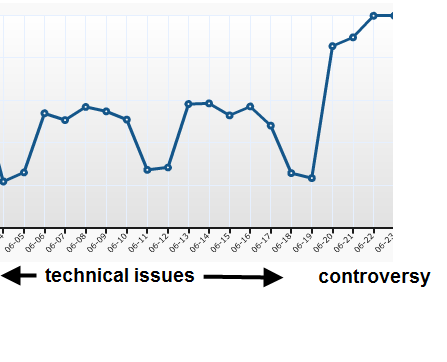

Just so you guys know, this is a chart of traffic on this blog. The first bit were two weeks when I behaved myself and just posted about technical issues. Notice what has happened in the last week when I’ve posted controversy. What sort of message am I supposed to take from this?

Kevin,

Again my intention is not to convince you to walk away from SW and what you find to be a better tool. As I said in my earlier post, we can argue that all day long and probably never agree.

But why can’t you speak directly to the topic of this thread? It seems you insist on talking about SE versus SW and I don’t anyone will be convinced either way. I have used 3D CAD for over 25 years starting with Personal Designer from Computervision… but that was 1985 and at the time was probably the best PC based 3D CAD system on the market. And back then Pro/E and solid modeling was still a dream. But Computervision let PD languish by only focusing on CADDS 5. But I was able to do things with PD that good old AC could only dream about in its 2.5D world, but Unfortunately due to poor management decisions by Computervision, PD stopped being developed by the mid 90’s. The “Better” product didn’t win back then, and that can happen again.

Nobody can doubt your commitment to SW by your posts… it just seems like your doing everything to avoid the real subject here. Where is SW headed… maybe the clouds if we’re to believe Mr. Ray.

But just remember that the beauty of the marketplace is that we get to choose our tools based on our individual needs. And nothing is better for ALL of us when you have 2 or 3 companies trying to gain market share through product improvements. What I believe the folks at Siemens/Solid Edge have determined is that 90% of the people using SW,SE, and AC, and for whom surfacing is NOT a top priority, there’s plenty of reasons to look at how much more productive they’ll become using ST4… and for the others, well they’re probably using a “real” Industrial Design package such as Alias or NX, etc. for their surface modeling. Point is that they aren’t interested in you as their customer… well right now! So stop defending your position…. it’s valid and nobody is trying to convert you. So even though the enthusiasm for Solid Edge might seem like a “Mexican Wave of Cheer” to you, to those who have had the time to experience ST4, see your seemingly bitter reaction as nothing more but a “Bronx Cheer”, then an honest assessment of the product.

@Kevin Quigley

PTC is apparently adding Freestyle (equivalent to Tsplines) to its foundation Creo parametric package for free. A serious blow to solidworks.

@Dave Ault

Dave I looked at it earlier this year when we had a new start so I think it was ST3. To be honest I was not that serious about buying it as the price was too high.

I dont consider it a toy. But I don’t consider it as a viable option for my business due to the surfacing and the fact that the long term contracts we have in place for production work are based around SolidWorks master assemblies and DriveWorks set ups. The simple fact is that imported geometry might be the killer feature of ST but we rarely handle imported parts (or rather we rarely have to edit them). 99% of our work is new content creation or reconfiguring assemblies we have created.

So just to be clear I’m not dissing SolidEdge or it’s users but rather just trying to put an alternative reality across that seems to be forgotten in the Mexican wave of cheer that seems to be following SolidEdge. At the end of the day you pick your CAD tool based on your workload and skills. I have never had cause to doubt I’d made the right decision going with SolidWorks and despite all the activity in the CAD Market now I still don’t.

There is a major area you are forgetting Kevin where there is no substitute for direct editing, imports. Yes quite often much original creation is a wash time wise but it is what happens after that which is powerfull. Like a family of parts for instance. Or the edits to catch a change in design by customers who can’t make up their minds. Initial parts creation is only part of the equation.

How seriously did you look at ST and what version? I am just curious to see why you consider it a toy.

I must be the only one that looks forward to the V6 implementation into SW. V6 is very powerful and any improvement over what SW has now is a step in the right direction. The only thing I see other companies doing is sending the model through a meat grinder to try get it to interact with their other platforms. I suppose V6 will address this in a lot of different ways by standardizing on a single kernel. I guess I have a hard time believing that SW would come out with a product that is worse than the product they have now? I think patience is the key here and those who wait will reap the rewards.

@Bob Mileti

Sorry Bob, I’m not nit picking when it comes to surfacing. that is my day job and I use those tools every single day. I do happen to be rather eclectic with CAD systems in that I started in SolidWorks in 97, added Ashlar-velum to the mix in 98 (due to the lack of surface=ing in SW at the time), added ThinkDesign/Shape in 2000 for the surfacing, switched from ThinkDesign to VX in 2003 for surfacing, before returning to SolidWorks (as the core system) in 2006 again because SW surfacing was finally as good as or better than the best of the rest (or rather – more usable and more robust than the best of the rest).

When in comes down to it I have two concerns – can I model what I want to model and can I do that modelling in a cost effective manner (ie I can meet deadlines). Surfacing is critical to me for that process.

I don’t have a beef with anyone. My points were that I have been in this business long enough to see systems come and go and to see past the hype that surrounds new technology releases. It does, at the end of the day, come down to cost of implementation. I am quite sure NX direct surface modelling is probably the best on the market right now. But for the price of one seat of NX with advanced surfacing I can buy 3 , possibly 4 seats of SolidWorks, or 1 seat of SolidWorks plus a good designer for 9 months. I know what I’d make more money on.

@Kevin Quigley

Kevin,

First off I don’t think anyone at Siemens/Solid Edge expects a mass exodus from SW over to SE/ST and Sync. And that’s not what I believe Matt Lombard and many of us Solid Edger user here are expecting either.

But If the CEO Tony Affuso said what Mr Ray said I’d be quite nervous too. So your nit picking on things like Solid Edge’s poor surfacing, I take with a grain of salt since we can argue all day long over which product does surfacing better, but we all know that at the end of the day, our biases are what we cling to.

Again this isn’t I believe a discussion about which product is better, but which company has the right focus… and for everyone probably reading these comments here, it’s about who is listening to their customer and who is investing in making their product better.

Personally my hope is that SW responds to the Siemens/Solid Edge challenge and ups the anti. I never want the SE Development folks to sit back and rest as I think SW has… and as end users, we all get the benefit.

So your beef is with Mr. Ray, not Solid Edge or its dedicated users. For me, my “3 years of subs” as you call it, has paid off in spades.

Bob

@Kevin Quigley

Kevin,

Yeah, Ive done a surfacing comparison, and SE is lacking. http://www.dezignstuff.com/blog/?p=4139

They take on machine design because it is the biggest market segment, and with all the prismatic geometry, it’s the place the current technology fits best.

What I like best about the direct edit side is that you can change the design intent without having to resketch stuff. Also, you apply the intent directly to the model rather than fiddling around with a list of sketches and rebuild times. You can make in-context type changes without debilitating relations between parts.

And then the times when you can mix and match history-based with direct, like make your prismatic casting model and put fillets on as ordered features. This means fillets will never wreck your direct edits, and will always be intelligent. Same with shells and other features that need to be highly adaptable.

Move Face doesn’t even begin to compare, especially when you consider the Live Rules.

Besides the conceptual, SE is better implemented from an interface workflow point of view as well.

To be fair, I’m not considering the cost. I’m not selling anything, just looking at tools.

Thanks for another point of view.

One other thing. I see many comments comparing SolidWorks to PTC. Is this a bad thing? Far as I know PTC are doing very nicely thank you. They have (probably) the best modelling kernel around and now with Creo are finally getting a better user interface. Last time I looked the installed user base of Pro/E was still huge. Seimens don’t release financials so all we rely on is what their marketing department says.

If I ever considered switching it would more than likely be to PTC. In the UK SolidEdge is an expensive option….more than SolidWorks and more expensive for subs. Funny that. I happen to know how much some folks here paid for their SolidEdge licenses! Lets just say if it was that price I’d have bought 3 seats! And that my friends is the big issue for the customer outside the USA.

It has taken Solid Edge 3 releases for ST to become usable to many-so that is 3 years of subs funding development. And they say Seimens aren’t good at marketing?

I have looked at ST and SolidEdge but it is not for me. It strikes me that the time required to properly set up a model to do history like edits is considerably more than I can manage now. But more critically SolidEdge is a product that is restricted-the surfacing is nowhere near as robust or as powerful as SolidWorks. The SolidEdge marketing machine seems to have hoodwinked it’s users into this “focus on machine design”. Why? I suspect because they need to flog NX at several times the price to users that need “advanced surfacing”.

But honestly I have yet to see a demo of direct modelling in SolidEdge ST that I could not achieve in SolidWorks using Move Face or a simple delete faces and remodel operation. Like a lot of things in CAD the focus on demos is on pre-existing geometry. What interests me is how you create the geometry and edit it then. In that scenario there is little benefit of direct modelling.

@Bob Mileti

Excellent observations Bob. Very much lays out what I am thinking as a SolidWorks customer.

@Dave Ault

Very well said Dave Ault. The only thing I’d add is that Siemens/Solid Edge Marketing and Development are 98% focused on Solid Edge. Yes there is talk of SW and AC thrown around. but that’s not their focus. The focus is PURELY on us the Users and in making Sync Technology work the way WE work… not some corporate marketing gimmick from the clouds above. The success of Sync Technology is with the USERS and this is what’s giving Siemens their success.

If any of you SW users had access to the Sold Edge user newsgroup over the past few years, you would have become familiar with me as one of Sync harshest critics. But after many years of unbelievable effort and LISTENING on the part of the Solid Edge Development team, they have delivered more then any of us could have hoped for…. and that was ST3. ST4 has added even more refinement and user requested enhancements. Where ST3 made working in both History and Direct modeling environments seamless, ST4 has polished the GUI and streamlined the process to the point where working with Solid Edge is a really fun experience. It’s nice sometimes to be proven wrong… very wrong indeed!

But again Siemens/Solid Edge is not focused on just beating SW… they are focused on one goal… simply make SE/Sync the best product. The question for the SW user base is this: No matter how SW responds now, they’ll always be chasing Sold Edge and Sync. As Dave points out changing the SW Kernel is going to be a distraction at best, and as he mentioned Sync is NEVER coming to SW. And it took 2+ years for Sync to settle into the powerhouse it is today. But during this same period Dassualt/SW seems to be just milking their users good will for the bottom line. When and if they finally give you the road map, will it be another 2 to 3 years before you’ll know if SW has evolved into that same vision? Or will it follow PTC’s Pro/E that simply lives off of its reputation from 10+ years ago and always hopelessly in a state of desperation. As a Solid Edge user, SW’s success doesn’t directly effect me. Why? Well personally I have great product in SE/Sync, and it makes me a lot more productive today then 2+ years ago. And that’s how I earn my living and Siemens/Solid Edge folks understand that and not because I’m a Siemens stock holder.

I am not trying to bash SW here, since its a good product, and after ST1 I seriously thought of jumping ship. But we all know how hard switching CAD products is. Anyway I can’t help but see the similarities between Dassault/SW and how PTC’s arrogance let them squander their market prominence to a young brash upstart. But Sold Edge is not young, but it is “brash”, and that should worry Dassault/SW even more. With its $100+ Billion parent corp. financial backing, 50% annual sales growth, and seasoned 20+ years Professionals like Dan Staples and his team…. this is not some “brash upstart” but a formidable force who’ve developed some amazing technology that is going to be hard to catch up to. Question is will Dassault make the necessary investment and better yet will it be the right investment.

So the next few years should prove interesting for MCAD market… But as customers, we get to decide on which side of this battle we want to participate! But again either way, we the user wins…. Solid Edge has upped the anti with a very successful technology. The question again is will Dassault step up to the challenge, or are they just to big and will devolve into another PTC.

This sounds like a SLIGHTLY biased perspective. Used to sell SWx until 2005? Selling SE today I presume?

Conrad,

Biased? Only because I recognize when a company is working for customer needs and when its working for its own needs. I don’t have any financial relationship with either company, although I do have a solution partner relationship with SW for writing books.

My SW file reduced in size by a factor of 2 when it was save as a copy with a new name. So that leaves a factor of 600 to go. Of course if the name is not changed it doubles in size. Have you ever looked at the data in a SW model? The low information density is astounding! The information about features that are long ago deleted is worthless.

SE files could not possibly be that stupid.

Interesting discussion on the opportunity presented by SE in uniting Parametric and Direct technologies.

The approach is novel, but I beleive that we at Autodesk have taken an even more revolutionary approach allowing users to move between the two environments without having to make an explicit choice.

Learn more here:

http://labs.autodesk.com/technologies/fusion/getting_started/

Rick: Give this a try…

Tools, Options, Performance , VOF on rebuild. Then hit CTRL+Q and do a file save as. This might bring you file size down considerably.

How big are SE files compared to SW? I am so sick of the giant SW files. SW files contain junk left over from every deleted feature and body all in a bulky sloppy format. The essence of a SW part definition is 1200 times smaller than a Solidworks file.

@Imics13

I agree. We use Solid Edge with 32 bit machines and several hundred to a few thousand part assemblies and have no issues with assembly performance. There are also many users who have embraced Synchronous modeling and use it for 100% of their models. Many more are using it in “mixed mode”. Once you understand it and become comfortable, you won’t go back.

Agree with you Dan, ST4 Event was an spectacular launch that gives us the opportunity to share the voice with customers and partners about the Wide Leadership of Solid Edge and the future of CAD as we know it so far. @rolyhermida

Awesome blog post Matt! Once again you’re showing the real history to the MCAD market. Thanks for mention my twitt and congrats to the good view you have from the market 🙂

@dkbana

You are right about ST3 being the first “useable” version. ST4 from what I saw at the rollout was primarily a lot of improvements to create vastly improved predictability and reliability of ST and to improve the work flow to be better than it was. According to what Dan Staples said they are focusing on geometry creation. I heard nothing about upcomming aps that are primarily window dressings like cloud stuff or IPAD/POD stuff or 5 different rendering programs. It was all about being the best and most reliable mid range MCAD program.

Lets face it, when SW knocked PTC off their throne PTC did not go away. Neither will SW go away but for the forseeable future the advancing technology is with ST. The Parasolid kernal is what direct editing resides on and don’t think for one second they are going to share this ST technology with anyone. This leaves others to implement their idea of direct editing on top of the kernal. Or the other alternative which is perhaps the way SW will go and that is to see what can be done to do it with the Catia kernal. I think Dassault is having a lot of trouble doing this and thus we hear nothing about progress and we see no successfull examples. I am not a fly on the wall at Dassault but I imagine after the damage Jeff “Death” Ray has done the debate still rages about what to do and how to do it. The other thought is that this comes straight from the very top of Dassault and that would be even worse.

What it really amounts to is that SW is owned by a company that has become a bloated bureauracracy and has forgotten what made them great. Into this void will step a company that is hungry and has new stuff and a better way. I think it will be SE. When I was there at the rollout my thought after the first day was that this must have been what it was like at one of the SW events where everyone stood around and realised that everything was coming together for SW to be the best. It must have been exciting to be there and I figure that the Huntsville ST4 rollout will be regarded in the same light in the future.

It is a shame when the driving force of a cad company is that we have your legacy files in our format and we hope you regard it as to much bother to switch because of that little fact.

ah no sorry Matt… I understand the server is bbsnotes.plms-eds.com and there are 8 or so groups but I think it still requires an account and password???

perhaps a SE user or employee can provide the details 🙂

btw does SE have a manual in pdf form or is it online? I’d like to read through it.

Well. I´m Solid Edge User but 2 years ago i was thinking to move to SW, Why? because the focus on machinery design, that change with the time. my point of view here is that ST4 open a hole on the CAD market of SW and Inventor. I´m Sure that ST5 will help to jump SE to 3rd place to the 2dn one. everyone wants a Software that is buildit with “what the customer wants”. if in 4 or 5 months they develop from st3 to st4 imagen what they will make in 10 making ST5.

From the PDM side of things…. Their Teamcenter Mobility solution looks very promising. They get need for true mobile access throughout the organization.

http://www.plm.automation.siemens.com/en_sg/products/teamcenter/teamcenter-mobility/support.shtml

And still a eDrawings app for iOS is M.I.A.

…sigh.

There are many things I like about the Creo vision (small “apps”, dealing with complex configurations, common data structures, etc. But we’ll just have to wait and see how PTC executes on the vision.

I think all this commotion could be a good thing for the industry as a whole. There’s been too much complacency and stagnation in the CAD world for way too long.

-Jim Anders

http://www.linkedin.com/profile/view?id=46242228

@Alessandro

Hi,

SE [Home PC, Win7 64bit 6Gb Nvidia Geforce 9600GT and AMD processor] is very good in large assy and very quick. More better than SW. 🙂

Here is an example, this contains ~238000 parts.

[img]http://www.dezignstuff.com/blog/wp-content/uploads/2011/06/ganz_ossz.jpg[/img]

Using SW since 1999, I was very dis-satisfied with the last four or five years of bloat-adding, poor performing “enhancements”. Performance enhancements was my first request for the last five years.

I was quite surprised with SW2011. Almost no new features added (I just looked at the “what’s new” and it reads more like a “corrected bugs” list) but usability has improved a lot!

Almost no crashing, no “failed to save” messages…

But most important I think is the performance improvements. I tried to never use operations like “delete face” or “move face” before because they would slow rebuilds too much but they are now as fast as other operations.

Save times are also quite faster; saving a PDF from a drawing would take as much as four minutes in SW2010 and is now a matter of a few seconds. For me SW2011 delivered! (a few years late)

I think SW would now most benefit from usability enhancements. They shouldn’t be afraid to go beyond their current paradigms and explore new methods and questions current ones. Like how we must choose top-down, bottom-up, best ways to convey design intent… I feel I must frequently trick it to get what I need and not risk being painted in a corner if the project goes in an unsuspected direction (and it always does here).

Time to get creative!

Well, something to blog about.

Over in DS SolidWorks land nothin’ goin’ on, at all. Hopefully all talk about the Cloud is dead (as we all read about Cloud security leaks on a daily basis). I’m waiting for the 2012 DS SolidWorks Roll Out this fall to see if anything new is offered.

However, most of my customers seem content with the DS SolidWorks Status Quo as they just now upgrade to Windows 7. They’re happy with the overall performance of Windows 7 64Bit, but poor large assembly/drawing performance is still the major problem with the existing DS SolidWorks application(using the much of the same code since 1995,16 years ago!, that’s 160 years in computer years).

Perhaps another change to the Color, oops Appearance, feature is coming…

Yawn,

Devon Sowell

@Neil

Neil, I wasn’t aware of that change. Could you give a link for the news group?

@Mark

Yeah, well, I can see that people might have moved away from ST1 & 2. If you look back on this blog, my reaction to those wasn’t very good either. ST3 finally delivers.

@Johnny

Johnny, I didn’t say SE ST3 or 4 was going to put SolidWorks away, I said it’s going to put SE on the map, and start down the road to greater market share. If it happens at all, it will take some time for SE to even catch up.

@solidworm

In SW, Move Face leaves a history-based feature in the tree. Those features add to rebuild times. In SE, direct edit changes leave no record. Because there is no list of features (for the direct edit portion) there is no rebuild time, only time to display. Move Face is also very limited when it comes to the kinds of things that will choke it, compared to SE. So, yes, direct edit is like a “smart Move face”, if you like, but a very smart Move Face to the point that it hardly compares. That’s one difference. Also, SE uses what it calls “Live Rules”, which essentially assign intelligence to model faces on the fly rather than having to rely on sketches. Face selection options are MUCH stronger in SE as well. SE can also have a history-based section of the tree, which seems best used for things like fillets and shell. In SW, you’re stuck with history, even for direct edit type changes. In SE, you can work either way or mix methods. What’s not to like?

How’s solidedge’s combined history and direct editing different than solidworks history+move face? I’ve seen its somehow smart,for example grabbing a face from a patterned cut, it can resize the entire pattern instances. isn’t it a smart solidworks move face?

Hi Matt,

we have to wait untill SW2012 came out.

ST in history free is not used by users.

ST is only used in history mode.

It’s true that SW lacks in direct modeling, but the focus is performance.

SolidEdge lack in performance and nobody want spend time in workaround for open assembly with more then 100 parts.

SolidWorks has good tools to open assembly.

It’s also true that SW must focus in modeling and assembly more.

So this is the version of SE that finally puts SW away? Funny, I’ve been hearing that since 1997.

That’s funny you say people will be moving from Works to Edge for SyncTech. We have had several customers look to SW because they did not want Sychronous Technology.

>The Solid Edge News Group is no longer a closed group. This means that you do not need a valid Webkey in order to create an account. The group is now open to anyone who cares to join in on the Solid Edge conversation.

might start listening in… 😉